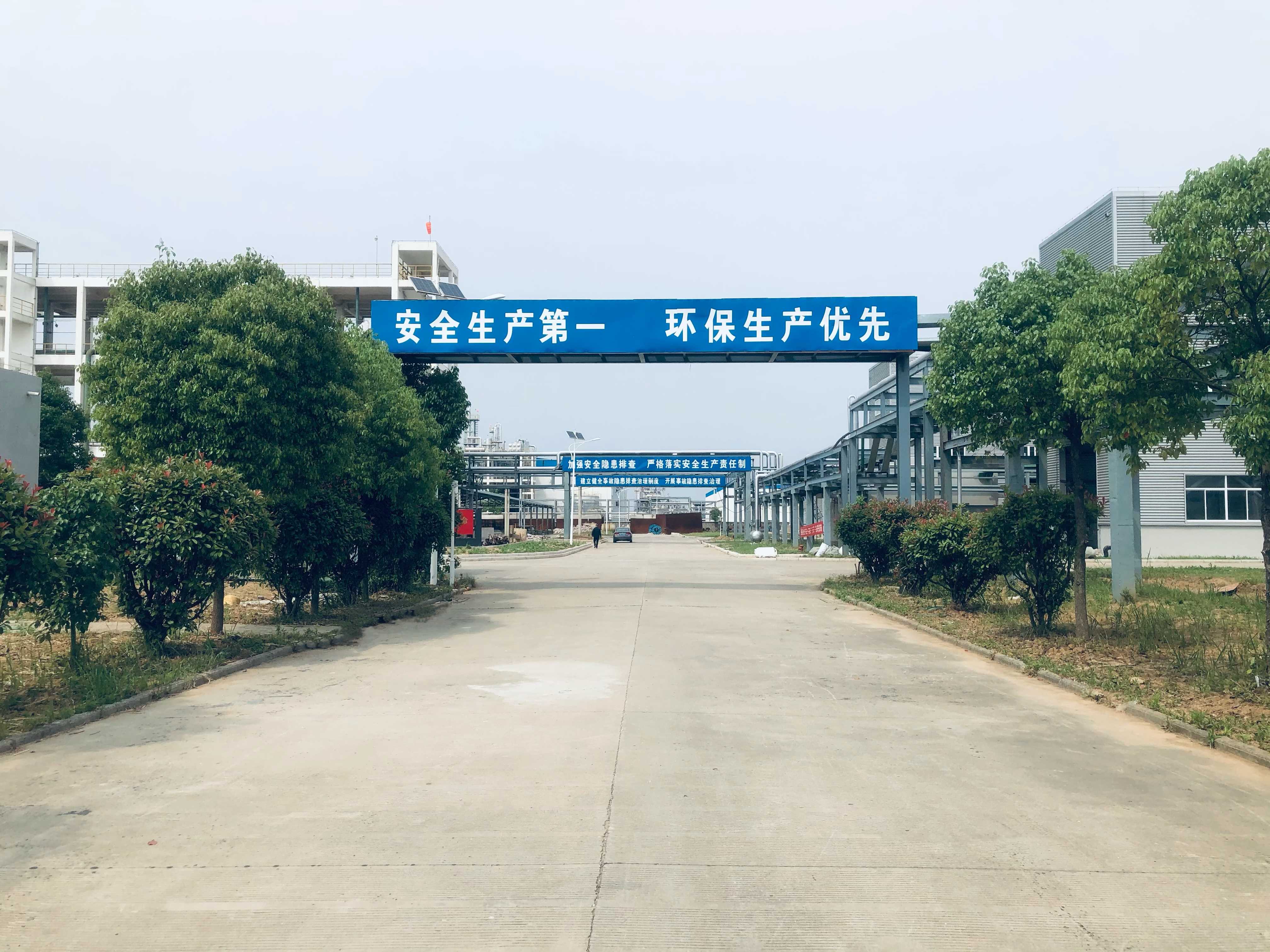

42004A 4000T/year Insoluble Sulfur Production Line

Tag No. : 42004A

Name: 4000T/year Insoluble Sulfur Production Line

Insoluble sulfur (IS) is a type of isomer of numerous sulfur elements, which is a long chain linear polymer with a molecular weight of tens of thousands. Chemical thermodynamics calls it polymeric sulfur, and its valuable characteristic is that it is insoluble in rubber and solvents. However, the structural group is unstable and spontaneously converts into rhombic sulfur. There is less than 1% in nature, and complex physical and chemical reactions are necessary to prepare high content, high thermal stability, and high dispersibility insoluble sulfur oil filled products. Typical specifications include HS, HD, and OT20.

The preparation process of insoluble sulfur mainly includes contact method, gasification method, melting method and radiation method.

Contact method with hydrogen sulfide and sulfur dioxide as raw materials, through the reactor with acid medium for contact reaction, can produce insoluble sulfur. The product of the reaction is a mixture of soluble sulfur and insoluble sulfur, which is washed, dried, crushed, extracted and other processes to obtain insoluble sulfur. Radiation method refers to the production of insoluble sulfur by radiation of sulfur polymer in acidic medium. This process route has not been industrialized.

The gasification method and melting method are based on the theory of thermal phase transformation of sulfur chemistry. The polymer region of sulfur is about 160℃~190℃, so the chemical process should make the high polymerization sulfur in this temperature region, form spherical droplets with particle size ≤30μm, disperse turbulent flow in the quenching liquid fog, and then quickly cool and quench, the sulfur phase transformation is terminated. The stabilizing agent in the quenching liquid coupling the double-terminal free electrons of IS can obtain high dispersion and high thermal stability of IS, and also can obtain high reaction conversion rate. Through analysis, practice has proved that the "one-step gasification method", namely the gasification solvent quenching process, is successful.

The "one-step gasification" production process technology of high-performance insoluble sulfur.

|

Product name |

Raw material name |

Specification |

Unit consumption |

Annual consumption |

|

HDOT20 (4000 t / year) |

Industrial liquid sulfur |

99.50% |

2.209 |

8836 |

|

Naphthenic oil |

100% |

0.195 |

780 |

|

|

CS2 |

98% |

0.021 |

84 |

|

|

Composite stabilizer |

99% |

0.014 |

56 |

|

|

Electricity |

/ |

683.25kWh |

2.733×106kWh |

|

|

Steam |

0.8MPa |

72×104 |

||

|

Nitrogen |

98% |

72m3 |

14.4 × 105m3 |

|

|

Sulfur powder for rubber (4000 t / year) |

Solid sulfur |

99.50% |

1.001 |

4004 |

|

Electricity |

/ |

537.125kWh |

2.148×106kWh |

For more details, please feel free to contact us by email sales@wintekgroup.com

Key Words: Insoluble Sulfur, Sulfur Dioxide, Rubber Sulfur Powder

Product Center

Request for Quotation

CONTACT INFORMATION

Mobile: +86 18936090872

Tel: +86 512 69552989

Email: sales@wintekgroup.com

Skype ID: rongqiang.wang

Telegram/Whatsapp/Wechat ID:+86 18936090872

OFFICIAL WECHAT

QUICK LINKS

- Homepage

- about us

- Hardware Display

- software display

- development process